MBR

MBR

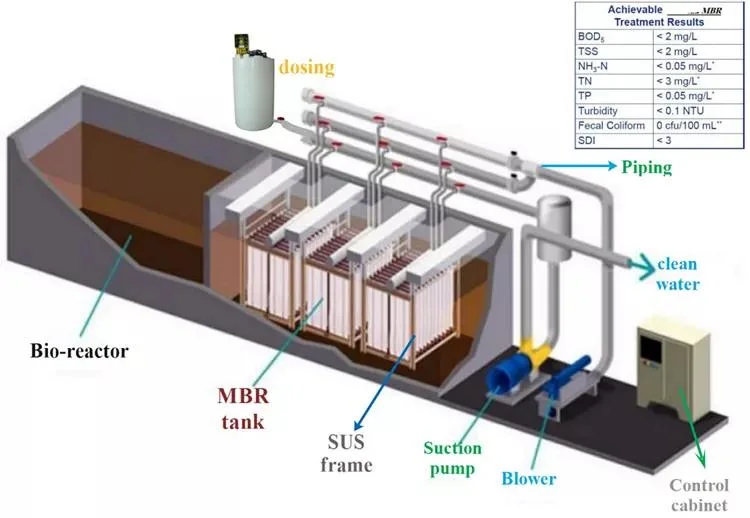

Membrane Bioreactor (MBR) System combines a conventional activated sludge treatment with a membrane liquid-solid separation process.

SPECIFICATIONS

of the product

THE BIOLOGICAL MEMBRANES

The membrane process is a very important separation process in water and waste water technology, which becomes increasingly competitive and is superior to the traditional Activated Sludge Process. Membrane Bioreactor (MBR) is an Advanced Wastewater Treatment Technology. The most widely applied membrane separation processes are microfiltration (MF), ultra filtration (UF), nano filtration (NF), reverse osmosis (RO) . The separation ranges are as follows:

100 to 1000 nm for MF, 5 to 100 nm for UF, 1 to 5 nm for NF, and 0.1 to 1 nm for RO.

Membranes are usually made from different plastic and ceramic materials, but metallic membranes also exist. The most widely used materials are celluloses, polyamides, polysulphone, charged polysulphone and other polymeric materials such as polyacrylonitrile (PAN), polyvinylidene difluoride (PVDF), polyethylsulphone (PES), polyethylene (PE), and polypropylene (PP). All of these polymeric materials have a desirable chemical and physical resistance.

THE MBR SYSTEM ELEMENTS

The membrane Filter ( membrane and support frame) The Laser-welded Plate-and-Frame Membrane Plate is the key element of the membrane filter. Membrane Module is a complete unit consisting of membrane plates; support frame, feed inlet retentate, and outlet permeate ports.

- Permeate withdrawal system

- Air scouring blower system

- Permeate & mixed liquor recirculation pumps

- Membrane cleaning system

- Programmable logic controllers (PLCs)

The MBR Working Principle

Based on precise engineering calculations, a predetermined amount of raw waste water is pumped to the MBR aerated tank, by securing the necessary conditions for bacterial growth, almost all the organic load in the water will be oxidized within the set HRT. The vacuum pump’s pressure is adjusted to suck the waste water through the membrane at a rate equal to the raw water inlet rate. Since the filter will block all particles ≥than 40 nano in the water ,the effluent water passing through the filter will be clean enough to be reused. The fouling forming on the membrane’s outside surface is backwashed by air pressure . The excess amount of sludge accumulating in the tank is discharged every month.

REFERENCE

- 150 M3/day system for Heet spital -Heet -Iraq

- 200 M3/day system for Basra Hospital-Basra -Iraq

- 250 M3/day system for Najaf Maternity Hospital -Najaf -Iraq

- 250 M3/day system for Baghdad Specialized Hospital -Baghdad